1.Business Backpack

1.1 Market Demand Analysis

1.2Mainstream Materials and Specifications

-

Fabric: 300D-1680D nylon (higher density looks more premium), PU leather (business-like but not durable), genuine leather (high-end), waterproof polyester (practical)

-

Lining: 210T polyester lining or 190T pongee, high-end models use velvet lining to protect laptops

-

Zippers: YKK size 5 or 8 are standard, high-end models use YKK waterproof zippers

-

Hardware: mostly matte black or gun-color hardware accessories to enhance business aesthetics

1.3 Core Production Processes

-

Heat-pressed back panel: Use EVA or PE board heat-pressed molding to provide rigid shape and back support

-

Laptop compartment protection: Independent compartment uses 8-15mm thick EPE pearl cotton or velvet, passes drop test

-

Reinforced stitching: Stress points use triple back-stitch or X-shaped reinforcement to ensure 30-50kg load-bearing

-

USB charging port: Reserved internal wire channel, external opening needs waterproof treatment

1.4 Cost Factors

-

Material cost difference between genuine leather and high-end PU can reach 3-5 times

-

YKK zippers cost 40-60% more than ordinary zippers, but failure rate is 10 times lower

-

Thickness and quality of shockproof material in laptop compartment directly affects protection performance

-

Hardware plating process (ordinary vs vacuum plating) affects corrosion resistance

1.5 Procurement Suggestions

2.Casual Daypack

2.1 Market Trend Analysis

2.2 Mainstream Materials and Specifications

-

Canvas: 8oz, 12oz, 16oz canvas, higher weight means more durable but heavier

-

Polyester: 300D-600D polyester, lightweight and low cost

-

Recycled materials: rPET recycled polyester, eco-friendly selling point attracts young consumers

-

Blended fabrics: cotton-linen blend, polyester-cotton blend, pursuing natural texture

2.3 Core Production Processes

-

Printing process: screen printing (large batch), digital printing (small batch multiple styles), heat transfer (complex patterns)

-

Embroidery customization: flat embroidery, 3D embroidery, appliqué embroidery, increases brand recognition

-

Color blocking: splicing different color fabrics to increase design sense

-

Washed vintage: canvas material enzyme washed or sand washed to create retro style

-

Webbing customization: jacquard webbing, printed webbing replace ordinary webbing

2.4 Cost Factors

-

Printing process complexity: single-color screen printing has low cost, digital printing with more than 4 colors increases cost by over 50%

-

Customization level: big difference in sampling fees and MOQ between standard and fully customized styles

-

Fabric selection: canvas is 30-50% more expensive than polyester, but has better texture

-

Accessory material: plastic buckles vs metal buckles, cost difference about 20-30%

2.5 Suggestions

Fast style changes but low mold investment, suitable for small batch, multi-style parallel development.

3.School Backpack

3.1 Market Demand Analysis

3.2 Mainstream Materials and Specifications

-

Fabric: 600D polyester (most commonly used, good wear resistance), 900D polyester (enhanced version)

-

Coating: PVC waterproof coating or PU coating, water repellent grade 3-4

-

Back panel: EVA spine protection board (5-10mm thick) or PE board

-

Shoulder straps: thickened mesh shoulder straps (filled with 8-15mm EVA or memory foam)

-

Reflective materials: 3M reflective strips or reflective printing, meeting EN13356 standard

3.3 Core Production Processes

- Spine protection system design: S-shaped shoulder straps disperse pressure, fit ergonomic curves

- EVA back panel molding: heat-pressed molding process, 5-10mm thickness, balancing support and comfort

- Pressure-reducing chest buckle: adjustable height chest buckle, fixes shoulder straps to prevent slipping

- Reflective strip sewing: 3M reflective material heat-cut then sewn, ensuring 50+ meter night visibility

- Reinforcement process: triple back-stitch at shoulder strap and bag body connection, diamond reinforcement at bottom stress points

3.4 Cost Factors

-

Spine protection system complexity: simple EVA back panel vs multi-layer structure spine protection system, cost difference 30-50%

-

Safety certification fees: European and American markets need EN71, CPSIA and other certifications, testing fees $500-2000

-

Reflective material grade: 3M genuine reflective strips are 2-3 times more expensive than ordinary reflective materials

-

Fabric weight: price difference between 600D and 900D polyester is about 15-20%

3.5 Suggestions

School backpack safety certification cycle is long (4-8 weeks), and inspection time needs to be planned in advance. For European and American markets, EN71 (EU) and CPSIA (US) are mandatory requirements, and non-compliant products will be removed or recalled. Spine protection function is the core selling point, and it is recommended to confirm with the factory the EVA density of the back panel (≥40kg/m³) and resilience test data. Reflective materials should use 3M Scotchlite or similar grade products to ensure 50-meter night visibility distance. Back-to-school season stocking needs to be ordered 3-4 months in advance to avoid insufficient capacity during peak season. Educational institution centralized procurement projects have low profit margins but large and stable quantities, and separate quotations are recommended.4.Hiking Backpack

4.1 Market Size Analysis

4.2 Mainstream Materials and Specifications

-

Fabric: Cordura 500D-1000D nylon (king of wear resistance), Ripstop tear-resistant nylon (420D-840D)

-

Coating: PU or silicone coating, waterproof grade 1500mm-3000mm

-

Bottom: thickened 1680D or double-layer fabric reinforcement

-

Zippers: YKK size 8 or 10 zippers, main compartment uses two-way zippers

-

Webbing: 25mm width high-strength nylon webbing, load-bearing 150kg+

4.3 Core Production Processes

1.Carrying system:

- Simple: EVA back panel + ordinary shoulder straps (entry level)

- Adjustable: adjustable shoulder straps and waist belt, suitable for different heights

- Suspension: mesh back panel + aluminum alloy internal frame, best breathability (high-end)

4.5 Cost Factors

4.6 Procurement Suggestions

5.Cycling Backpack

5.1 Market Demand Analysis

The growth of urban commuting cycling population (environmental awareness, health concepts, traffic congestion) has driven the expansion of the cycling backpack market. European countries’ bicycle-friendly policies and infrastructure construction make the region the largest market. Road cycling and mountain cycling have different functional requirements for backpacks and require segmented product lines. Corporate cycling clubs and cycling event sponsorships also provide B-end procurement opportunities.5 mm or it flaps at 30 km/h.

5.2 Mainstream Materials and Specifications

- Fabric: 210D-420D waterproof coated nylon, lightweight and water-repellent

- Back panel: 3D three-dimensional breathable mesh back panel for sweat drainage

- Reflective materials: large area reflective printing or reflective strips

- Waterproof zipper: main compartment recommended to use waterproof zipper or waterproof zipper cover

- Helmet net: elastic mesh external helmet holder

5.3 Core Production Processes

-

Streamlined cutting: narrow design close to back reduces wind resistance

-

Breathable back panel system: 3D three-dimensional mesh + EVA support strips ensure air circulation

-

Reflective design: 360-degree reflective system meeting EN13356 standard

-

Waterproof roll-top: top roll-top design for quick closure in rain

-

Cycling-specific compartments: tool compartment (for tire repair tools), water bag compartment, helmet fixation

5.4 Cost Factors

-

Breathable back panel mold fee: 3D three-dimensional molding requires special mold, single cost $500-1500

-

Reflective material grade: EN13356 certified reflective materials are 3-5 times more expensive than ordinary reflective

-

Waterproof zipper: 80-120% more expensive than ordinary zippers, but better waterproof performance

-

Fabric waterproof coating: price increases with 1000mm, 3000mm, 5000mm waterproof grades

5.5 Procurement Suggestions

Safety of cycling backpacks is a rigid requirement in European and American markets, and reflective materials must provide EN13356 test report (50-meter visibility distance). It is recommended to design reflective elements on shoulder straps, chest, back, and sides to form 360-degree visibility. Breathability is equally important, as obvious back sweating problems during summer cycling can be significantly improved with 3D back panels. Capacity is usually 10-20L, larger sizes will affect cycling balance. For the European market, waterproof performance needs to reach IPX4+ (can withstand rainy riding). Reasonable compartmentalization of tool compartments is a reflection of professionalism, and it is recommended to match sizes with cycling tool brands (such as Park Tool).6.Ski Backpack

6.1 Market Characteristics Analysis

6.2 Mainstream Materials and Specifications

- Fabric: PU coated nylon, waterproof grade 5000mm+

- Insulation layer: aluminum foil insulation layer or wool lining (goggle compartment)

- Low-temperature materials: TPU and webbing that won’t harden at minus 20 degrees

- Waterproof zippers: YKK waterproof zippers or Aquaguard zippers

- Reinforced bottom: 1680D wear-resistant material, not easy to wear when contacting snow

6.3 Core Production Processes

1.Ski board fixation system:

- A-frame fixation (double-board skiing): diagonal cross fixation of snowboards

- Diagonal fixation (single-board skiing): vertical fixation of single board

6.4 Cost Factors

- Waterproof grade: price difference between 3000mm and 10000mm waterproof coating is 40-60%

- Fixation system complexity: simple straps vs professional fixtures, affects $3-8 cost

- Avalanche airbag: high-end models equipped with airbag system, cost increases $50-150

- Low-temperature testing: materials need to pass minus 20-30 degree low-temperature testing, increases certification cost

6.5 Procurement Suggestions

7. Travel Backpack

7.1 Market Recovery Analysis

7.2 Mainstream Materials and Specifications

- Fabric: 600D-1680D waterproof polyester, wear-resistant and easy to clean

- Mixed canvas: polyester-cotton blend, combining texture and practicality

- Anti-theft materials: inner anti-cut steel wire mesh (mid-to-high end)

- Zippers: YKK size 8 or 10 zippers, main compartment two-way zippers

- Wheels and trolley: high-end models equipped with silent universal wheels and aluminum alloy trolley

7.3 Core Production Processes

- 180-degree U-shaped large opening: opens fully like suitcase for easy organization

- Expandable design: zipper expansion layer, capacity can increase 5-10L

- Hidden shoulder strap system: shoulder straps can be stored in back panel zipper compartment, protect straps and allow hand carry or luggage rack hanging

- Independent laptop compartment: TSA-friendly design, no need to remove computer at security

- Multi-functional compartments: independent compartments for shoes, wet items, toiletry bags, etc.

7.4 Cost Factors

- Hardware zipper quantity: large opening design requires long zippers (80-100cm), increases cost

- Internal compartment complexity: big difference in sewing time between 5 compartments vs 10 compartments

- Wheels and trolley: silent universal wheels + aluminum alloy trolley, increases cost $8-15

- Expandable zipper: additional zipper and fabric increase cost about $2-3

7.5 Procurement Suggestions

8.Camera Backpack

8.1 Market Segmentation Analysis

8.2 Mainstream Materials and Specifications

- Fabric: 1680D waterproof nylon, wear-resistant and scratch-proof

- Shockproof material: 10-15mm thick PE foam or EPE pearl cotton

- Dividers: detachable Velcro dividers for flexible space adjustment

- Lining: soft velvet or microfiber to prevent lens scratches

- Tripod fixation: side or bottom straps, load-bearing 3-5kg

8.3 Core Production Processes

- Modular divider system: detachable dividers, Velcro fixed, free combination of space

- Quick-access side or bottom door: no need to put down backpack, quick camera access from side/bottom

- Three-layer protection structure: outer waterproof, middle shockproof foam, inner velvet

- Independent laptop compartment: 13-15 inch computer compartment for editing needs

- Tripod fixation system: elastic strap + bottom fixing buckle for stable carrying

8.4 Cost Factors

- Divider quantity and quality: detachable dividers cost $0.8-2/piece, standard 5-8 pieces

- Quick-access door hardware: side or bottom opening zipper increases cost $2-4

- Shockproof foam thickness: price difference of 30% between 10mm and 15mm thickness

- Waterproof grade: 3000mm vs 5000mm coating affects outdoor shooting applicability

8.5 Procurement Suggestions

9. Tactical Backpack

9.1 Market Demand Analysis

9.2 Mainstream Materials and Specifications

- Fabric: 1000D Cordura nylon (DuPont authorized USA), 500D-1000D high-strength polyester

- Zippers: YKK size 10 heavy-duty zippers, some use YKK waterproof zippers

- Webbing: 25mm standard MOLLE webbing, 38mm spacing (1.5 inches)

- Hardware: military-spec buckles, D-rings, corrosion-resistant plating or black oxide treatment

- Waterproof coating: PU or TPU coating, waterproof grade 3000-5000mm

9.3 Core Production Processes

- 25mm width webbing, sewn at 1.5-inch spacing

- Each row of webbing back-stitched for reinforcement, load-bearing 10-15kg

9.5 Cost Factors

- Cordura genuine authorization: genuine hangtag requires authorization fee but has high brand premium

- MOLLE webbing quantity: full-coverage MOLLE vs partial MOLLE, increases material and labor by 40-60%

- Military-spec test fees: MIL-STD-810 durability test, MIL-STD-461 electromagnetic compatibility test, etc., $500-2000 per item

- Modular accessories: standard 2-3 accessory pouches vs separate sales, affects overall pricing strategy

9.6 Procurement Suggestions

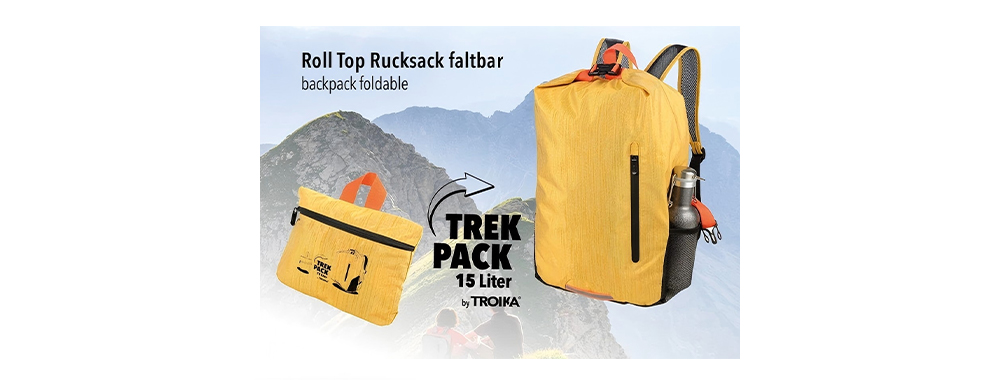

10. Foldable Backpack

10.1 Market Positioning Analysis

10.2 Mainstream Materials and Specifications

- Fabric: 30D-210D ripstop polyester, lightweight and tear-resistant

- Waterproof coating: PU or silicone coating, water repellent grade 3-4

- Storage pouch: integrated design, bag body folds into its own pouch

- Zippers: nylon or resin zippers, lightweight priority

- Webbing: 15-20mm lightweight webbing to reduce overall weight

10.3 Core Production Processes

- Ultrasonic pressing: seamless connection technology, reduces sewing weight and improves waterproofness

- Integrated storage pouch: storage pouch connected to bag body, stuffed into pouch after folding

- Minimalist design: reduce unnecessary accessories and decorations, pursue lightest weight

- Reinforce key points: although lightweight, stress points like shoulder straps and handles still need reinforcement

- Waterproof zipper cover: add waterproof seam tape or flap at main compartment zipper

10.4 Cost Factors

-

Fabric lightweight degree: 30D, 70D, 210D, lighter is more expensive but load-bearing decreases

-

Folded volume: good compression performance requires precise calculation, higher sampling fee

-

Waterproof coating grade: price difference of 20-30% between ordinary water repellent vs high-grade waterproof

-

Logo printing area: large-area printing increases process cost but has good brand exposure effect

10.5 Procurement Suggestions

| Backpack Type | Capacity Range | Main Materials | Core Processes Production | Cycle Technical | Threshold Main | Application Scenarios |

| Business Backpack | 15-30L | Nylon/Leather | Laptop shockproof, USB port | 30-45 days | Medium | Corporate group purchase, business travel |

| Casual Daypack | 15-25L | Canvas/Polyester | Printing customization, color blocking | 25-35 days | Low | Daily commute, student use |

| School Backpack | 20-35L | Polyester | Spine protection system, reflective strips | 30-40 days | Medium | Primary/secondary students, training institutions |

| Hiking Backpack | 40-80L | Cordura | Carrying system, external points | 40-60 days | High | Multi-day hiking, mountain expedition |

| Trail Running Pack | 5-15L | Ultra-light nylon | Seamless pressing, water bag compartment | 35-50 days | High | Marathon, trail running events |

| Cycling Backpack | 10-25L | Waterproof nylon | 3D cutting, reflective system | 30-45 days | Medium | Urban cycling, road/mountain biking |

| Ski Backpack | 20-35L | Waterproof materials | Ski board fixation, insulation layer | 40-55 days | Medium-high | Skiing, winter outdoor |

| Travel Backpack | 30-50L | Polyester | U-shaped opening, hidden shoulder straps | 35-45 days | Medium | Short travel, business travel |

| Backpacker Pack | 50-90L | High-strength nylon | Adjustable carrying, multiple external points | 45-60 days | Medium-high | Long-term travel, backpacker routes |

| Camera Backpack | 15-30L | Shockproof materials | Modular dividers, quick-access door | 35-50 days | Medium-high | Photography travel, commercial photography |

| Tactical Backpack | 20-45L | 1000D | MOLLE system, modular | 40-60 days | High | Military/police, emergency rescue, outdoor |

| Foldable Backpack | 10-20L | Ultra-light polyester | Ultrasonic pressing, integrated storage | 20-30 days | Low | Promotional giveaway, travel spare |

Summary: How to See B-End Product Layout Logic from “Backpack Type”

From the B-end perspective, the backpack industry is not a single low-threshold category, but is composed of multiple sub-tracks: volume-driven, design-driven, and technical function-driven. The differences in material selection, production processes, and cost structures of different backpack types directly determine their suitable market positioning and cooperation models.

For purchasers and brand owners, rather than pursuing “complete product line”, it is better to prioritize identifying which categories truly match their own channels, customer groups, and supply chain capabilities. Technical backpacks test factories’ R&D and testing capabilities more, while fast-moving consumer backpacks rely more on flexible production and rapid iteration capabilities.

Only by conducting product planning based on full understanding of various backpack manufacturing logics can we establish more stable and long-term valuable B-end cooperation relationships beyond price competition.